There are three theories as to when the earliest canned food in China was produced: one is that Guangdong native Zhang Guangyuan invested 100,000 taels of silver to establish the Guangmaoxiang canning factory in Guangzhou in the 19th year of Guangxu's reign in the Qing Dynasty (1893); In the 32nd year (1906), Taifeng Food Company, the first domestic canned food company, was established in Shanghai with an investment of 70,000 taels of silver to produce Shuangxi brand canned poultry meat; it is also said that it was established in the 30th year of the reign of Emperor Guangxu of the Qing Dynasty (1904). In 2006), Ran Longze, a native of Jiangjin, Chongqing, founded the Jianxin Factory at the inclined bridge of Fushouchang, Jiangjin County (now Jinfu Town, Jiangjin City). The factory employed 223 people and produced cans and fruit wine. Thus, the first cannery factory in Chongqing and even western my country was born. The following year, that is, the 31st year of Guangxu (1905), Ran Xizhi and Ran Junyi, students studying in Japan, purchased Japanese handmade can-making equipment and set up a factory in Jimen, Chongqing, to produce cans.

At the beginning of the 20th century, canneries began to be established in various parts of China. In 1908, a group of patriots and overseas Chinese in Fujian, with a sincere heart to save the country through industry and revitalize China, raised funds to set up a ceramic cannery in Neicuowo, Gulangyu Island, Xiamen, and introduced some American canneries. Canning processing equipment produces canned foods such as coriander hearts and black bean pickled melons with the local flavor of southern Fujian, which are exported to Hong Kong and Southeast Asia. The products are very popular among Hong Kong and overseas Chinese; in 1913, the Army Dry Food Factory outside the south gate of Changsha, Hunan Province produced Canned meat, fruits and vegetables, among which canned turtles were sold to Japan, canned fruits and vegetables were sold to Germany; etc.

China's canned food industry did not enter the normal development track before 1949. The quantity, scale and technical level could not be called a real industry. After 1949, China's canned industry began a new milestone.

Just as the American Civil War promoted the rapid development of the American canning processing industry, before the founding of the People's Republic of China, China's canning processing industry had not yet formed. In 1949, the total canning production in China was less than 500 tons. After the founding of the People's Republic of China, especially during the period of resisting U.S. aggression and aiding Korea, China's canning industry developed rapidly due to the need for military cans. Shanghai Yimin Food Factory No. 1 was the main manufacturer of military cans at that time. From the beginning of the War to Resist U.S. Aggression and Aid Korea in October 1950 to the end of the War to Resist U.S. Aggression and Aid Korea in July 1953, China's canned food production increased sharply from 1,733 tons in 1950 to 27,854 tons in 1953. The absolute increase in production in three years reached 1,507%.

After that, as a member of the socialist camp, all walks of life in China followed the example of the Soviet Union at that time, and the canning industry was no exception. With the assistance of the Soviet Union, many canning processing companies were established in various places to produce various cans in the direction of socialism. National camp exports. In 1958, China's canned export volume reached 95,257 tons, approaching the 100,000-ton mark. But then, with the beginning of the Great Leap Forward, the cooling of Sino-Soviet relations, and the three years of natural disasters from 1961 to 1963, China's canned industry went on a downward slope. Especially during the three years of natural disasters, China's canned production fell below 100,000 tons. , only more than 70,000 tons. After the breakdown of Sino-Soviet relations, China's canned food played the role of repayment materials, and also became a stepping stone for China to seek trade with the West. Through private trade, canned food began to be exported to Japan, the United States and Europe. In 1973, China's canned exports exceeded the US$100 million mark for the first time. At a time when China was in very short supply of foreign exchange, it played a role as a major foreign exchange earner and received much attention from the government.

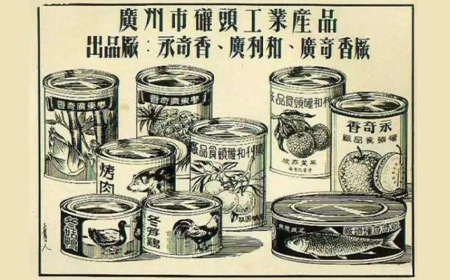

In the planned economy era when China was relatively short of various materials, China's canned industry was mainly tasked with earning foreign exchange from exports, and only some products that could not be exported were circulated in the domestic market. At that time, canned food was considered a high-end consumer product in China and was often given as a gift for visiting relatives, friends and patients. As the volume of trade with the West continued to grow, canning companies across China began to emerge, and for a time it became one of the most active industries in the food industry, creating a number of outstanding canned brands, such as Meilin, Daffodil, Great Wall, Pearl River Bridge, etc. brand.

In the era of planned economy, the main development goal of China's canned industry is to earn foreign exchange through export. Even during the Cultural Revolution, which was recognized as the "Ten Years of Catastrophe", or in the early days of reform and opening up, the development of China's canned food industry never stopped.

China's canned industry in the era of planned economy was like a huge canned group company. In 1958, there were 22 canned export enterprises in China designated by the former Ministry of Light Industry, and the number increased year by year thereafter. The former State Commodity Inspection Bureau acted as the group's quality control department and did not allow canned products that did not meet standards to be sold abroad, otherwise it would damage the reputation of Chinese canned goods. The local grain and oil import and export companies dominated by COFCO are equivalent to the group's foreign trade department, responsible for exporting cans produced by canneries to countries around the world, and using the same or different brands depending on the factory and product. For example, canneries in Fujian Province use the "Daffodil" brand for export, canneries in Tianjin and Henan use the "Great Wall" brand, canned meat in Shanghai and Sichuan use the "Meilin" brand, and canneries in Guangdong use the "Pearl River Bridge" brand. Card. At that time, in addition to the above-mentioned, Chinese canned export brands also included the "Xiangshan" brand, "Tiantan" brand, etc. This is the "integration of industry, trade and inspection" system for the canned industry in the era of planned economy.

In order to develop the canned food industry, the former Ministry of Light Industry also invested in the construction of canned light industrial machinery manufacturing plants. For example, the Guangdong Shantou Light Industrial Machinery Factory was built in 1957 and became an enterprise directly under the Ministry of Light Industry in 1966. It was the leading manufacturer of canned food processing machinery and equipment in China at that time. Key enterprises (now "Shantou Light Industry Machinery Factory Co., Ltd."). Shantou in Guangdong, Zhoushan in Zhejiang, and Jiujiang in Jiangxi are the three main producing areas of canning light industry machinery in the era of planned economy.

Before the reform and opening up, almost all canneries had their own can-making workshops. Since tinplate, the can-making material, had to be imported, the light industry bureaus in various places had to go to the Ministry of Light Industry to approve tinplate quotas every year, and then distributed the quotas to various factories in the province. cannery.

In 1973, China's canned export earnings exceeded US$100 million for the first time, and five years later, it exceeded US$200 million in 1978, US$300 million in 1980, and US$400 million in 1986. US$460 million jumped to US$620 million. Export volume exceeded 500,000 tons in 1988, setting a record high of 560,000 tons. State-owned canning enterprises in various places have grown steadily, playing the glorious role of "star enterprises" and "major profits and taxes" in various places. They have also become popular factories for employment of workers in the state-owned enterprises in various places. Shanghai Meilin Cannery, Guangxi Nanning Cannery, Zhangzhou Cannery, etc. have become the standard bearers in the industry.

With the implementation of the reform and opening up policy, the business model of "integration of industry, trade and inspection" under the state-owned system has changed. Private canning factories have spread rapidly. The export trade of private canning factories uses the dual-track trade system to go through unplanned trade channels. At this time, the state-owned trading system also underwent fundamental changes. The canned brands jointly created by various factories under the state-owned system were owned by the state-owned trading company COFCO Industrial Foods. Factories that did not obtain COFCO brand authorization meant losing export channels. Many companies After switching to self-operated export, since there is no right to use the brand, it can only accept OEM processing. State-owned trading companies with brands can designate multiple factories for production. The chaotic pattern of brand authorization resulted in wide variations in product quality for the same brand at that time. Serious and disorderly competition occurred in China's own canned brand consumer market, mainly in Southeast Asia. Some canned companies that could not obtain brand authorization even took risks and used their brands. On the other hand, export regulatory agencies have also experienced regulatory loopholes due to policy reforms, and problems such as the fraudulent use of export factory codes have continued to occur. During the transition period, China's canned food industry developed tenaciously and brutally amidst chaos.

An industry insider recalled: “The state-owned canning enterprises at that time hated the abuse of code names and spoke out loudly about the loopholes in code name management, so much so that the directors of the three major state-owned canning enterprises in Fujian Province jointly submitted a bloody letter, and a group of Fujian commodity inspection officials were fired as a result. But now we need to look at this problem in two parts from a historical perspective. The loopholes in code management during the transition period are also the product of the conflict between the domestic management system in the planned economy era and the development trend of the market economy. If the export trade management system at that time had been changed to With today's management system, such a phenomenon will not happen. In fact, the loopholes in code management have exactly helped the development of private canning companies."

1989 is destined to be an unforgettable year in the development history of China's canned food industry. This year, the "Enterotoxin Incident of Canned Mushrooms Exported to the United States" occurred, which can be described as the most tragic event in the history of the development of China's canned food industry. The incident is briefly described as follows -

February 1989: US media reported that many food poisoning incidents had occurred in the United States, saying that canned mushrooms imported from China were used in the food that caused the food poisoning. The U.S. Congress held a hearing on the matter and tasked the FDA with handling the matter.

May 19: The FDA notified all U.S. import ports: "No matter what the shape of the 10# canned mushrooms produced in China, they will be automatically detained and will not be subject to sampling inspection!" It also stated that there have been 4 confirmed cases of canned mushrooms produced in China. There have been more than 100 cases of related poisoning incidents.

September 22: China’s former Ministry of Economy and Trade, the former State Administration of Commodity Inspection, the former Ministry of Light Industry and the National Grain and Oils Corporation negotiation team reached an understanding with the United States, that is, except for a few cannery products included in the automatic detention list, imports are temporarily prohibited, and other products in the Products from canneries registered in the United States can still be released for import if they pass inspection by both parties (including enterotoxin inspection); in terms of enterotoxin inspection methods, both parties use TECRA enterotoxin detection kits (hereinafter referred to as TECRA kits) produced by the Australian PTY Company ) as a means.

October 13: The U.S. FDA notified the Commercial Office of the Chinese Embassy that they have revised the import warning on May 19: to expand automatic detention—that is, to implement "full automation" on products from 59 Chinese mushroom canning processing plants registered in the United States. detain"!

After that, other Chinese canned mushroom importing countries such as Canada, Japan, and the European Union followed the United States and successively introduced import restrictions on Chinese canned mushrooms.

At that time, almost all canneries in China were processing canned mushrooms, and the southern provinces such as Guangdong, Fujian, Guangxi, Jiangxi, Zhejiang, and Sichuan were hardest hit. As the largest exporter of canned mushrooms in China at that time, the state-owned canneries in Fujian Province were the first to bear the brunt. As a result, the Zhangzhou Canned Food Factory, the largest manufacturer of canned mushrooms at that time, was on the path to extinction, and the Fuzhou Canned Factory closed down as a result. Even the Huangyan Cannery Factory in Zhejiang Province suffered a loss of more than 20 million yuan, and the company has never recovered since. Industry insiders recall that period of history and pointed out: In order to protect the interests of mushroom farmers, the government at that time allowed state-owned enterprises to purchase mushroom raw materials even though they knew that the products could not be sold after they were manufactured. This resulted in a large amount of inventory that was ultimately disposed of at a loss and at a price reduction. This conflict and contradiction between the system and the market economy became more prominent after the "enterotoxin incident", and the final result was to push the state-owned canning enterprises onto the path of decline.

The Chinese Commodity Inspection Department has carried out research on "canned mushroom enterotoxin" for several years, and has gone through three international conferences. Finally, in October 1999, the third "International Conference on Mushroom Biology and Mushroom Products" was held in Sydney, Australia. At the conference, researchers from the Chinese research team once again gave a special speech and comprehensive explanation on this matter on behalf of the Chinese inspection and quarantine department, fully proving the common fact that Australian TECRA enterotoxin detection kits have false positives, and also proved that mushroom raw materials and canned Even if Staphylococcus aureus is contaminated during processing, due to the mutual constraints of various external factors, Staphylococcus aureus cannot multiply to the point of producing enterotoxin, let alone produce "enterotoxin" in canned mushrooms. In the face of a large amount of facts and scientific data, TECRA enterotoxin detection kit has been proved to be a "Pandora's box". It also shows that the FDA’s 1989 conclusion that Chinese canned mushrooms were contaminated with “staphylococcal enterotoxin” using TECRA enterotoxin detection kits was incorrect.

The above is the famous "Mushroom Enterotoxin Export to the United States Incident" in the history of China's canned food industry. Affected by this period, after 1989, a large number of state-owned canning enterprises entered the track of closure, merger, bankruptcy and bankruptcy.

After Deng Xiaoping's speech during his southern tour in 1992, the reform and opening up process further accelerated. Before 2000, a large number of state-owned canning companies in China's canning industry went bankrupt one after another, while a large number of private companies rose rapidly, and Sino-foreign joint venture canning companies also rushed to follow suit. Private and Joint ventures have gradually become the core strength of China's canning industry. Before entering the new century, except for the three state-owned enterprises of Shanghai Meilin, Xiamen Gulong, and Guangzhou Eagle Money, most state-owned canneries have entered the restructuring stage, and many companies have begun the liquidation process of bankruptcy. Even if Nanning Cannery and Zhangzhou Cannery, which once ranked second and third in China, have production, some private operators only rent some workshops to process a small number of cans for export.

Although state-owned canneries began to die out in 1989, private companies rose rapidly. Industry insiders confirmed that after the Zhangzhou canning factory ceased production, a large number of technical and managerial personnel flowed to private canning companies, which quickly improved the technical and management strength of Zhangzhou's private canning companies. Until China joined the WTO in 2001, China's canned exports steadily increased amidst the lamentations of most state-owned enterprises. Even when the United States implemented anti-dumping against Chinese canned mushrooms in 1998, only a few state-owned canned enterprises that were still struggling due to regulatory constraints stopped breathing. In addition, after experiencing the storm, the overall development momentum of China's canned industry is good.

The decade from the end of 1989 to 2000 was a period of ownership transformation in China's canned industry, from state-owned canneries as the main body to private enterprises as the main body. Entering the new century, private canning enterprises have become the main force in China's canning industry. At the same time, the product structure of China's canned exports has begun to change, and the export scale of canned varieties such as tomato paste, yellow peaches, and aquatic products has begun to show substantial growth.

In 2001, China's canned export volume exceeded 1 million tons for the first time, reaching 1.19 million tons. With the bell ringing into the new century, China's canned food industry has ushered in a new stage of development.

In 2000, with the further deepening of economic system reform, the proportion of state-owned enterprises in China's canned food industry to the total industry assets has dropped to less than 25%, and has shown signs of rapid shrinkage. A large number of state-owned canned enterprises have suffered serious losses. It is in a state of suspension waiting for reorganization, restructuring, bankruptcy and liquidation. A group of private canning enterprises have completed primitive accumulation and are at the starting point of rapid expansion. As of 2015, there are only three state-owned canning companies in China's canned industry that have been strong since the planned economy era: Shanghai Meilin, Xiamen Gulong, and Guangzhou Eagle Money. These three canning companies are still well-known companies in the domestic canning industry.

The reform of the economic system has lifted the constraints of social relations on productivity. When building a cannery in the era of planned economy, in addition to the administrative approval required for food processing plants, you must also consider whether you can obtain export quotas; whether you can buy tinplate or empty cans; whether you can obtain an export code; and so on. There is no doubt that the "Industrial and Trade Inspection Integration" system in the history of China's canned industry played an indelible role in China's canned exports during the era of planned economy. However, after the reform and opening up, this old system no longer adapts to the new trends in industrial development. The situation has even become an old fence hindering industrial development. The Ministry of Light Industry was disbanded, and the foreign trade system of Grain and Oil Import and Export Company was reorganized into a system operated by local enterprises independently, and enterprises could export on their own. The former State Administration of Commodity Inspection became the Inspection and Quarantine Bureau after the "three inspections were integrated into one" and was later merged into the General Administration of Quality Supervision, Inspection and Quarantine. After establishing its own management system, the "Export Food Hygiene Registration System" was implemented in 2002 (changed to the "Export Food Production Enterprise Registration System" in 2011). This series of institutional reforms dismantled barriers that were incompatible with industrial development and greatly It has unleashed the potential of China’s canned industry development and export trade. It can be said that China's canned food industry has laid a good foundation for development before the arrival of the new century.

The specialization of empty can manufacturing has played a very positive role in promoting the development of China's can industry. In the state-owned era, every cannery had an empty can workshop to provide empty cans to the factory. Therefore, it was not easy to build a new cannery. After the reform and opening up, the number of private empty can manufacturing factories has gradually increased with the development of the can industry, and the iron printing and can making equipment has been continuously upgraded, especially the low-end can making equipment such as domestic automated resistance welding machines, flanging, rolling and sealing multi-station combination machines. Pricing has promoted the technological upgrading of the empty can manufacturing industry and the rapid expansion of enterprise scale, providing a good supply guarantee for the canning factory's demand for empty cans.

The process of localization of tinplate has also accelerated since entering the new century. Tinplate manufacturers such as Baosteel, Uni-President, Zhongyue, Jinhengban, and Shougang have completely changed the situation of relying on imports during the planned economy period. As of 2015, China's current total tinplate production capacity is said to have exceeded 10 million tons.

The purpose of canned processing and export under the market economy is not only to earn foreign exchange, but also to receive the attention and policy support of local governments as an effective way to solve the "three rural" issues. Many canning companies have been rated as leading agricultural industrialization enterprises in local and even China. The chairman of Hunan Guoxiu Food (Group) Co., Ltd., an orange canned processing company in Yongzhou, Hunan, was elected as a representative of the National People's Congress for two consecutive terms in 2008. During the two sessions every year, he submitted many proposals for the development of China's canned industry, becoming Today's outstanding representatives of China's canned industry fully prove from another aspect that governments across China attach great importance to the canned industry.

In order to develop the local economy, various local governments have made great efforts to organize and coordinate the cultivation of canning raw materials. The continuous expansion of raw material planting bases such as Xinjiang tomatoes, Hubei oranges, Shandong asparagus and yellow peaches, Jiangsu yellow peaches and mushrooms, and Anhui yellow peaches ensures the demand for raw materials for canning processing.

Before the global financial crisis in 2008, China's agricultural raw material resources and labor advantages were very obvious, and Chinese canned products with high quality and low price had obvious competitive advantages in the international market. The international market has even expanded market consumption due to the low prices of Chinese products. After occupying the markets of developed countries such as Europe, the United States, and Japan, China's canned food market has expanded to Africa, the Middle East, Russia and other Eastern European countries. The fundamental reason why tomato paste, canned mushrooms, canned oranges, canned peaches and other varieties have grown rapidly and maintained high export volumes for many years is the comprehensive expansion of the international market.

In 2000, China exported 970,000 tons of canned goods, with an export value of US$740 million. Among them, the top five largest export varieties are canned white mushrooms (export volume 184,000 tons, export value 144 million US dollars), canned citrus (175,000 tons, 119 million US dollars), and canned tomato paste (153,000 tons, 0.68 billion US dollars), canned boiled bamboo shoots (volume per piece >= 8Kg) (92,000 tons, US$97 million), canned asparagus (83,000 tons, US$74 million). These five major varieties accounted for 70% of the total export volume and 68% of the total export value that year.

In 2001, China joined the WTO, and the foreign export trade system was further liberalized. The canned industry, with private enterprises as the main body, competed with hundreds of rivals. The production capacity and output of bulk canned export varieties increased rapidly. At the same time, the phenomenon of product homogeneity became increasingly serious. Disorderly competition in the industry has further intensified. But in any case, China's canned export volume has increased year by year, exceeding 1 million tons in 2001, 2 million tons in 2005, 3 million tons in 2011, and fluctuating around 2.9 million tons after 2012. Export volume exceeded US$5 billion in 2014, setting a record high.

From the beginning of the new century to 2012, China's canned industry experienced a 12-year golden growth period. Even with the outbreak of the global financial crisis in 2008, China's canned exports were still growing year by year in the four years from 2008 to 2012.

China's canned export trade in the new century has not been smooth sailing. The world's first "special safeguard measures" were implemented by the EU on canned oranges exported from China to the EU in 2003. The "special protection case" was changed to an anti-dumping investigation in 2008. 14 Chinese canned orange processing and export companies responded to the lawsuit. Zhejiang Taizhou Yican Food Co., Ltd. obtained the optimal tax rate for exports to the EU through responding to the lawsuit. Affected by this, the original more than 20 canned orange processing and export companies in Taizhou, Zhejiang began to decline, with only three or four remaining by the end of 2015. Australia and Mexico have also implemented anti-dumping duties on canned mushrooms from China. The melamine incident that broke out in China's dairy industry in 2008 was later hyped by Western media as the "Chinese food threat theory" and also had a negative impact on China's canned export trade. Japan’s “positive list system” has increased the inspection burden on Chinese canned export companies. The U.S. FDA took advantage of this situation and set up an office in China to conduct on-site inspections of factories exporting food to the United States at any time. The mandatory inspection of carbendazim residues in 2012 also had an impact on Chinese canned food export companies.

Since 2012, China's canned export trade has entered a period of stagflation due to the year-by-year increase in processing costs and the appreciation of the RMB, which has caused the competitive advantage of the products in the international market to weaken year by year. But fortunately, there has not been a cliff-like decline like some export-oriented industries. Therefore, it can be considered that the current operating pattern of China's canned export trade is generally stable. At the same time, in order to cope with foreign trade barriers and technical barriers, some outstanding companies have continued to explore base construction and full industry chain business models, and the level of production line automation has gradually improved.

In the 15 years since the beginning of the new century, China's canning processing enterprises have become very prominent in operating across provinces in order to obtain high-quality raw material resources. The Heze area of Shandong Province has attracted canning companies from Fujian and other places to build factories because of its rich asparagus planting resources; Xuzhou, Jiangsu, Suzhou, Anhui and other places have attracted many Zhejiang canned fruit processing companies to set up shop because of their rich yellow peach resources; Yichang, Hubei The rich raw material resources of the Yangtze River citrus belt have also introduced many Zhejiang canning companies.

The advantages of raw material resources directly trigger the expansion of the scale of the local canning industry, which in turn drives the further promotion of raw material planting. After several cycles, China's canning industry has formed industrial clusters dominated by regions and raw material types: Tomato paste in Xinjiang Industrial clusters; canned orange industry clusters in Zhejiang, Hubei, and Hunan; canned mushroom and canned aquatic product industry clusters in Zhangzhou, Fujian; canned fruit industry clusters in Xuzhou, Suzhou, and Linyi; canned meat industry clusters in Sichuan and Chongqing; canned meat industry clusters in Jieyang, Guangdong The canned bamboo shoots industry cluster; the Mengzong canned bamboo shoots industry cluster in Zhejiang and Fujian; the canned dace fish with black bean sauce industry cluster in Guangdong; the sweet corn industry cluster in Changli, Qinhuangdao;...

In 2015, China exported 2.91 million tons of canned goods, with an export value of US$4.98 billion. Among them, there are 7 tax codes with an export scale of more than 100,000 tons. The export volume of each tax code is as follows: canned tomato paste (>5kg) (export volume 564,000 tons; export value 499 million US dollars), canned tomato paste (≤5kg) ) (423,000 tons; US$415 million), canned citrus (318,000 tons; US$326 million), canned white mushrooms (185,000 tons; US$254 million), canned peaches (155,000 tons; US$189 million), Other canned vegetables (this is a separate tariff number listed by the customs, 129,000 tons; US$257 million), canned bamboo shoots (125,000 tons; US$205 million).

Compared with the international market, the expansion of China's canned domestic market is relatively slow. However, some regions and some varieties of canned products have developed rapidly mainly relying on the domestic market. The canned dace processing industry with black bean paste in Guangdong, the canned fruit processing industry in Pingyi County, Linyi County, Shandong Province, and the canned sweet corn processing industry in Changli, Qinhuangdao, etc. all developed by relying on sales in the domestic market. In addition, many canned food processing enterprises that relied on export trade began to focus on the domestic market after entering the new century, pursuing both domestic and foreign sales, and have also achieved certain results. Xiamen Gulong, Shanghai Meilin, Guangzhou Eagle Money, Xiamen Yinlu, Hunan Guoxiu, Guangdong Yuehua, Fujian Zishan, Fujian Xing, Fujian Gangchang, Shandong Linyi Kangfa, Shandong Linyi Tiantong, Zhejiang Fengdao, Fujian Quanzhou Xido A number of excellent brands such as Duo, Suzhou Technology and Qinhuangdao Marine Food have already occupied a certain share in the domestic market. Canned rice-treasure porridge, canned luncheon meat, canned braised meat, canned fruits from the north and south, canned dace with black bean sauce, canned meat sauce, canned tomato sauce, canned bamboo shoots, canned sweet corn, etc. have become the main force in China's domestic canned market.

There is a demand for military canned food every year, and many canned companies have obtained production orders through bidding. As disaster relief food, canned foods often become indispensable for food supplies in disaster areas. When the SARS epidemic broke out in Beijing in 2002, the canned products in the stores were sold out. Xiamen Gulong Canned Food Co., Ltd. worked overtime to produce canned meat rice dumplings with southern Fujian flavor and transported them by sea to Beijing to express condolences to medical workers fighting SARS; in 2008, the Wenchuan earthquake in Sichuan After the disaster, the first batch of food dropped by helicopter to the disaster area was canned meat produced by Sichuan Meining Canned Food Co., Ltd. With the deepening of international cooperation, Chinese canned goods have been continuously transported abroad through special channels for many years as supplies purchased by the United Nations or humanitarian relief supplies from China.

Since the National Bureau of Statistics includes protein drinks such as almond milk, coconut milk, and milk peanuts into the statistics of canned products, China's canned production has grown rapidly in recent years in terms of output. It can be believed that part of the substantial growth in domestic canned production released by the National Bureau of Statistics of China belongs to protein drinks and some flavored foods without added preservatives, including soft-packaged cans. The total output of canned food in 2015 was 12.126 million tons. It is calculated according to "total output - export volume + import volume = apparent consumption in the domestic market". Since the import volume is relatively small at first, it can be ignored, so China's domestic market in 2015 The apparent consumption of canned food in the year is 9.212 million tons. Based on the population of mainland China being 1.36 billion, the per capita consumption of canned food in China is 6.77 kilograms.

At the beginning of the 20th century, canneries began to be established in various parts of China. In 1908, a group of patriots and overseas Chinese in Fujian, with a sincere heart to save the country through industry and revitalize China, raised funds to set up a ceramic cannery in Neicuowo, Gulangyu Island, Xiamen, and introduced some American canneries. Canning processing equipment produces canned foods such as coriander hearts and black bean pickled melons with the local flavor of southern Fujian, which are exported to Hong Kong and Southeast Asia. The products are very popular among Hong Kong and overseas Chinese; in 1913, the Army Dry Food Factory outside the south gate of Changsha, Hunan Province produced Canned meat, fruits and vegetables, among which canned turtles were sold to Japan, canned fruits and vegetables were sold to Germany; etc.

China's canned food industry did not enter the normal development track before 1949. The quantity, scale and technical level could not be called a real industry. After 1949, China's canned industry began a new milestone.

Just as the American Civil War promoted the rapid development of the American canning processing industry, before the founding of the People's Republic of China, China's canning processing industry had not yet formed. In 1949, the total canning production in China was less than 500 tons. After the founding of the People's Republic of China, especially during the period of resisting U.S. aggression and aiding Korea, China's canning industry developed rapidly due to the need for military cans. Shanghai Yimin Food Factory No. 1 was the main manufacturer of military cans at that time. From the beginning of the War to Resist U.S. Aggression and Aid Korea in October 1950 to the end of the War to Resist U.S. Aggression and Aid Korea in July 1953, China's canned food production increased sharply from 1,733 tons in 1950 to 27,854 tons in 1953. The absolute increase in production in three years reached 1,507%.

After that, as a member of the socialist camp, all walks of life in China followed the example of the Soviet Union at that time, and the canning industry was no exception. With the assistance of the Soviet Union, many canning processing companies were established in various places to produce various cans in the direction of socialism. National camp exports. In 1958, China's canned export volume reached 95,257 tons, approaching the 100,000-ton mark. But then, with the beginning of the Great Leap Forward, the cooling of Sino-Soviet relations, and the three years of natural disasters from 1961 to 1963, China's canned industry went on a downward slope. Especially during the three years of natural disasters, China's canned production fell below 100,000 tons. , only more than 70,000 tons. After the breakdown of Sino-Soviet relations, China's canned food played the role of repayment materials, and also became a stepping stone for China to seek trade with the West. Through private trade, canned food began to be exported to Japan, the United States and Europe. In 1973, China's canned exports exceeded the US$100 million mark for the first time. At a time when China was in very short supply of foreign exchange, it played a role as a major foreign exchange earner and received much attention from the government.

In the planned economy era when China was relatively short of various materials, China's canned industry was mainly tasked with earning foreign exchange from exports, and only some products that could not be exported were circulated in the domestic market. At that time, canned food was considered a high-end consumer product in China and was often given as a gift for visiting relatives, friends and patients. As the volume of trade with the West continued to grow, canning companies across China began to emerge, and for a time it became one of the most active industries in the food industry, creating a number of outstanding canned brands, such as Meilin, Daffodil, Great Wall, Pearl River Bridge, etc. brand.

In the era of planned economy, the main development goal of China's canned industry is to earn foreign exchange through export. Even during the Cultural Revolution, which was recognized as the "Ten Years of Catastrophe", or in the early days of reform and opening up, the development of China's canned food industry never stopped.

China's canned industry in the era of planned economy was like a huge canned group company. In 1958, there were 22 canned export enterprises in China designated by the former Ministry of Light Industry, and the number increased year by year thereafter. The former State Commodity Inspection Bureau acted as the group's quality control department and did not allow canned products that did not meet standards to be sold abroad, otherwise it would damage the reputation of Chinese canned goods. The local grain and oil import and export companies dominated by COFCO are equivalent to the group's foreign trade department, responsible for exporting cans produced by canneries to countries around the world, and using the same or different brands depending on the factory and product. For example, canneries in Fujian Province use the "Daffodil" brand for export, canneries in Tianjin and Henan use the "Great Wall" brand, canned meat in Shanghai and Sichuan use the "Meilin" brand, and canneries in Guangdong use the "Pearl River Bridge" brand. Card. At that time, in addition to the above-mentioned, Chinese canned export brands also included the "Xiangshan" brand, "Tiantan" brand, etc. This is the "integration of industry, trade and inspection" system for the canned industry in the era of planned economy.

In order to develop the canned food industry, the former Ministry of Light Industry also invested in the construction of canned light industrial machinery manufacturing plants. For example, the Guangdong Shantou Light Industrial Machinery Factory was built in 1957 and became an enterprise directly under the Ministry of Light Industry in 1966. It was the leading manufacturer of canned food processing machinery and equipment in China at that time. Key enterprises (now "Shantou Light Industry Machinery Factory Co., Ltd."). Shantou in Guangdong, Zhoushan in Zhejiang, and Jiujiang in Jiangxi are the three main producing areas of canning light industry machinery in the era of planned economy.

Before the reform and opening up, almost all canneries had their own can-making workshops. Since tinplate, the can-making material, had to be imported, the light industry bureaus in various places had to go to the Ministry of Light Industry to approve tinplate quotas every year, and then distributed the quotas to various factories in the province. cannery.

In 1973, China's canned export earnings exceeded US$100 million for the first time, and five years later, it exceeded US$200 million in 1978, US$300 million in 1980, and US$400 million in 1986. US$460 million jumped to US$620 million. Export volume exceeded 500,000 tons in 1988, setting a record high of 560,000 tons. State-owned canning enterprises in various places have grown steadily, playing the glorious role of "star enterprises" and "major profits and taxes" in various places. They have also become popular factories for employment of workers in the state-owned enterprises in various places. Shanghai Meilin Cannery, Guangxi Nanning Cannery, Zhangzhou Cannery, etc. have become the standard bearers in the industry.

With the implementation of the reform and opening up policy, the business model of "integration of industry, trade and inspection" under the state-owned system has changed. Private canning factories have spread rapidly. The export trade of private canning factories uses the dual-track trade system to go through unplanned trade channels. At this time, the state-owned trading system also underwent fundamental changes. The canned brands jointly created by various factories under the state-owned system were owned by the state-owned trading company COFCO Industrial Foods. Factories that did not obtain COFCO brand authorization meant losing export channels. Many companies After switching to self-operated export, since there is no right to use the brand, it can only accept OEM processing. State-owned trading companies with brands can designate multiple factories for production. The chaotic pattern of brand authorization resulted in wide variations in product quality for the same brand at that time. Serious and disorderly competition occurred in China's own canned brand consumer market, mainly in Southeast Asia. Some canned companies that could not obtain brand authorization even took risks and used their brands. On the other hand, export regulatory agencies have also experienced regulatory loopholes due to policy reforms, and problems such as the fraudulent use of export factory codes have continued to occur. During the transition period, China's canned food industry developed tenaciously and brutally amidst chaos.

An industry insider recalled: “The state-owned canning enterprises at that time hated the abuse of code names and spoke out loudly about the loopholes in code name management, so much so that the directors of the three major state-owned canning enterprises in Fujian Province jointly submitted a bloody letter, and a group of Fujian commodity inspection officials were fired as a result. But now we need to look at this problem in two parts from a historical perspective. The loopholes in code management during the transition period are also the product of the conflict between the domestic management system in the planned economy era and the development trend of the market economy. If the export trade management system at that time had been changed to With today's management system, such a phenomenon will not happen. In fact, the loopholes in code management have exactly helped the development of private canning companies."

1989 is destined to be an unforgettable year in the development history of China's canned food industry. This year, the "Enterotoxin Incident of Canned Mushrooms Exported to the United States" occurred, which can be described as the most tragic event in the history of the development of China's canned food industry. The incident is briefly described as follows -

February 1989: US media reported that many food poisoning incidents had occurred in the United States, saying that canned mushrooms imported from China were used in the food that caused the food poisoning. The U.S. Congress held a hearing on the matter and tasked the FDA with handling the matter.

May 19: The FDA notified all U.S. import ports: "No matter what the shape of the 10# canned mushrooms produced in China, they will be automatically detained and will not be subject to sampling inspection!" It also stated that there have been 4 confirmed cases of canned mushrooms produced in China. There have been more than 100 cases of related poisoning incidents.

September 22: China’s former Ministry of Economy and Trade, the former State Administration of Commodity Inspection, the former Ministry of Light Industry and the National Grain and Oils Corporation negotiation team reached an understanding with the United States, that is, except for a few cannery products included in the automatic detention list, imports are temporarily prohibited, and other products in the Products from canneries registered in the United States can still be released for import if they pass inspection by both parties (including enterotoxin inspection); in terms of enterotoxin inspection methods, both parties use TECRA enterotoxin detection kits (hereinafter referred to as TECRA kits) produced by the Australian PTY Company ) as a means.

October 13: The U.S. FDA notified the Commercial Office of the Chinese Embassy that they have revised the import warning on May 19: to expand automatic detention—that is, to implement "full automation" on products from 59 Chinese mushroom canning processing plants registered in the United States. detain"!

After that, other Chinese canned mushroom importing countries such as Canada, Japan, and the European Union followed the United States and successively introduced import restrictions on Chinese canned mushrooms.

At that time, almost all canneries in China were processing canned mushrooms, and the southern provinces such as Guangdong, Fujian, Guangxi, Jiangxi, Zhejiang, and Sichuan were hardest hit. As the largest exporter of canned mushrooms in China at that time, the state-owned canneries in Fujian Province were the first to bear the brunt. As a result, the Zhangzhou Canned Food Factory, the largest manufacturer of canned mushrooms at that time, was on the path to extinction, and the Fuzhou Canned Factory closed down as a result. Even the Huangyan Cannery Factory in Zhejiang Province suffered a loss of more than 20 million yuan, and the company has never recovered since. Industry insiders recall that period of history and pointed out: In order to protect the interests of mushroom farmers, the government at that time allowed state-owned enterprises to purchase mushroom raw materials even though they knew that the products could not be sold after they were manufactured. This resulted in a large amount of inventory that was ultimately disposed of at a loss and at a price reduction. This conflict and contradiction between the system and the market economy became more prominent after the "enterotoxin incident", and the final result was to push the state-owned canning enterprises onto the path of decline.

The Chinese Commodity Inspection Department has carried out research on "canned mushroom enterotoxin" for several years, and has gone through three international conferences. Finally, in October 1999, the third "International Conference on Mushroom Biology and Mushroom Products" was held in Sydney, Australia. At the conference, researchers from the Chinese research team once again gave a special speech and comprehensive explanation on this matter on behalf of the Chinese inspection and quarantine department, fully proving the common fact that Australian TECRA enterotoxin detection kits have false positives, and also proved that mushroom raw materials and canned Even if Staphylococcus aureus is contaminated during processing, due to the mutual constraints of various external factors, Staphylococcus aureus cannot multiply to the point of producing enterotoxin, let alone produce "enterotoxin" in canned mushrooms. In the face of a large amount of facts and scientific data, TECRA enterotoxin detection kit has been proved to be a "Pandora's box". It also shows that the FDA’s 1989 conclusion that Chinese canned mushrooms were contaminated with “staphylococcal enterotoxin” using TECRA enterotoxin detection kits was incorrect.

The above is the famous "Mushroom Enterotoxin Export to the United States Incident" in the history of China's canned food industry. Affected by this period, after 1989, a large number of state-owned canning enterprises entered the track of closure, merger, bankruptcy and bankruptcy.

After Deng Xiaoping's speech during his southern tour in 1992, the reform and opening up process further accelerated. Before 2000, a large number of state-owned canning companies in China's canning industry went bankrupt one after another, while a large number of private companies rose rapidly, and Sino-foreign joint venture canning companies also rushed to follow suit. Private and Joint ventures have gradually become the core strength of China's canning industry. Before entering the new century, except for the three state-owned enterprises of Shanghai Meilin, Xiamen Gulong, and Guangzhou Eagle Money, most state-owned canneries have entered the restructuring stage, and many companies have begun the liquidation process of bankruptcy. Even if Nanning Cannery and Zhangzhou Cannery, which once ranked second and third in China, have production, some private operators only rent some workshops to process a small number of cans for export.

Although state-owned canneries began to die out in 1989, private companies rose rapidly. Industry insiders confirmed that after the Zhangzhou canning factory ceased production, a large number of technical and managerial personnel flowed to private canning companies, which quickly improved the technical and management strength of Zhangzhou's private canning companies. Until China joined the WTO in 2001, China's canned exports steadily increased amidst the lamentations of most state-owned enterprises. Even when the United States implemented anti-dumping against Chinese canned mushrooms in 1998, only a few state-owned canned enterprises that were still struggling due to regulatory constraints stopped breathing. In addition, after experiencing the storm, the overall development momentum of China's canned industry is good.

The decade from the end of 1989 to 2000 was a period of ownership transformation in China's canned industry, from state-owned canneries as the main body to private enterprises as the main body. Entering the new century, private canning enterprises have become the main force in China's canning industry. At the same time, the product structure of China's canned exports has begun to change, and the export scale of canned varieties such as tomato paste, yellow peaches, and aquatic products has begun to show substantial growth.

In 2001, China's canned export volume exceeded 1 million tons for the first time, reaching 1.19 million tons. With the bell ringing into the new century, China's canned food industry has ushered in a new stage of development.

In 2000, with the further deepening of economic system reform, the proportion of state-owned enterprises in China's canned food industry to the total industry assets has dropped to less than 25%, and has shown signs of rapid shrinkage. A large number of state-owned canned enterprises have suffered serious losses. It is in a state of suspension waiting for reorganization, restructuring, bankruptcy and liquidation. A group of private canning enterprises have completed primitive accumulation and are at the starting point of rapid expansion. As of 2015, there are only three state-owned canning companies in China's canned industry that have been strong since the planned economy era: Shanghai Meilin, Xiamen Gulong, and Guangzhou Eagle Money. These three canning companies are still well-known companies in the domestic canning industry.

The reform of the economic system has lifted the constraints of social relations on productivity. When building a cannery in the era of planned economy, in addition to the administrative approval required for food processing plants, you must also consider whether you can obtain export quotas; whether you can buy tinplate or empty cans; whether you can obtain an export code; and so on. There is no doubt that the "Industrial and Trade Inspection Integration" system in the history of China's canned industry played an indelible role in China's canned exports during the era of planned economy. However, after the reform and opening up, this old system no longer adapts to the new trends in industrial development. The situation has even become an old fence hindering industrial development. The Ministry of Light Industry was disbanded, and the foreign trade system of Grain and Oil Import and Export Company was reorganized into a system operated by local enterprises independently, and enterprises could export on their own. The former State Administration of Commodity Inspection became the Inspection and Quarantine Bureau after the "three inspections were integrated into one" and was later merged into the General Administration of Quality Supervision, Inspection and Quarantine. After establishing its own management system, the "Export Food Hygiene Registration System" was implemented in 2002 (changed to the "Export Food Production Enterprise Registration System" in 2011). This series of institutional reforms dismantled barriers that were incompatible with industrial development and greatly It has unleashed the potential of China’s canned industry development and export trade. It can be said that China's canned food industry has laid a good foundation for development before the arrival of the new century.

The specialization of empty can manufacturing has played a very positive role in promoting the development of China's can industry. In the state-owned era, every cannery had an empty can workshop to provide empty cans to the factory. Therefore, it was not easy to build a new cannery. After the reform and opening up, the number of private empty can manufacturing factories has gradually increased with the development of the can industry, and the iron printing and can making equipment has been continuously upgraded, especially the low-end can making equipment such as domestic automated resistance welding machines, flanging, rolling and sealing multi-station combination machines. Pricing has promoted the technological upgrading of the empty can manufacturing industry and the rapid expansion of enterprise scale, providing a good supply guarantee for the canning factory's demand for empty cans.

The process of localization of tinplate has also accelerated since entering the new century. Tinplate manufacturers such as Baosteel, Uni-President, Zhongyue, Jinhengban, and Shougang have completely changed the situation of relying on imports during the planned economy period. As of 2015, China's current total tinplate production capacity is said to have exceeded 10 million tons.

The purpose of canned processing and export under the market economy is not only to earn foreign exchange, but also to receive the attention and policy support of local governments as an effective way to solve the "three rural" issues. Many canning companies have been rated as leading agricultural industrialization enterprises in local and even China. The chairman of Hunan Guoxiu Food (Group) Co., Ltd., an orange canned processing company in Yongzhou, Hunan, was elected as a representative of the National People's Congress for two consecutive terms in 2008. During the two sessions every year, he submitted many proposals for the development of China's canned industry, becoming Today's outstanding representatives of China's canned industry fully prove from another aspect that governments across China attach great importance to the canned industry.

In order to develop the local economy, various local governments have made great efforts to organize and coordinate the cultivation of canning raw materials. The continuous expansion of raw material planting bases such as Xinjiang tomatoes, Hubei oranges, Shandong asparagus and yellow peaches, Jiangsu yellow peaches and mushrooms, and Anhui yellow peaches ensures the demand for raw materials for canning processing.

Before the global financial crisis in 2008, China's agricultural raw material resources and labor advantages were very obvious, and Chinese canned products with high quality and low price had obvious competitive advantages in the international market. The international market has even expanded market consumption due to the low prices of Chinese products. After occupying the markets of developed countries such as Europe, the United States, and Japan, China's canned food market has expanded to Africa, the Middle East, Russia and other Eastern European countries. The fundamental reason why tomato paste, canned mushrooms, canned oranges, canned peaches and other varieties have grown rapidly and maintained high export volumes for many years is the comprehensive expansion of the international market.

In 2000, China exported 970,000 tons of canned goods, with an export value of US$740 million. Among them, the top five largest export varieties are canned white mushrooms (export volume 184,000 tons, export value 144 million US dollars), canned citrus (175,000 tons, 119 million US dollars), and canned tomato paste (153,000 tons, 0.68 billion US dollars), canned boiled bamboo shoots (volume per piece >= 8Kg) (92,000 tons, US$97 million), canned asparagus (83,000 tons, US$74 million). These five major varieties accounted for 70% of the total export volume and 68% of the total export value that year.

In 2001, China joined the WTO, and the foreign export trade system was further liberalized. The canned industry, with private enterprises as the main body, competed with hundreds of rivals. The production capacity and output of bulk canned export varieties increased rapidly. At the same time, the phenomenon of product homogeneity became increasingly serious. Disorderly competition in the industry has further intensified. But in any case, China's canned export volume has increased year by year, exceeding 1 million tons in 2001, 2 million tons in 2005, 3 million tons in 2011, and fluctuating around 2.9 million tons after 2012. Export volume exceeded US$5 billion in 2014, setting a record high.

From the beginning of the new century to 2012, China's canned industry experienced a 12-year golden growth period. Even with the outbreak of the global financial crisis in 2008, China's canned exports were still growing year by year in the four years from 2008 to 2012.

China's canned export trade in the new century has not been smooth sailing. The world's first "special safeguard measures" were implemented by the EU on canned oranges exported from China to the EU in 2003. The "special protection case" was changed to an anti-dumping investigation in 2008. 14 Chinese canned orange processing and export companies responded to the lawsuit. Zhejiang Taizhou Yican Food Co., Ltd. obtained the optimal tax rate for exports to the EU through responding to the lawsuit. Affected by this, the original more than 20 canned orange processing and export companies in Taizhou, Zhejiang began to decline, with only three or four remaining by the end of 2015. Australia and Mexico have also implemented anti-dumping duties on canned mushrooms from China. The melamine incident that broke out in China's dairy industry in 2008 was later hyped by Western media as the "Chinese food threat theory" and also had a negative impact on China's canned export trade. Japan’s “positive list system” has increased the inspection burden on Chinese canned export companies. The U.S. FDA took advantage of this situation and set up an office in China to conduct on-site inspections of factories exporting food to the United States at any time. The mandatory inspection of carbendazim residues in 2012 also had an impact on Chinese canned food export companies.

Since 2012, China's canned export trade has entered a period of stagflation due to the year-by-year increase in processing costs and the appreciation of the RMB, which has caused the competitive advantage of the products in the international market to weaken year by year. But fortunately, there has not been a cliff-like decline like some export-oriented industries. Therefore, it can be considered that the current operating pattern of China's canned export trade is generally stable. At the same time, in order to cope with foreign trade barriers and technical barriers, some outstanding companies have continued to explore base construction and full industry chain business models, and the level of production line automation has gradually improved.

In the 15 years since the beginning of the new century, China's canning processing enterprises have become very prominent in operating across provinces in order to obtain high-quality raw material resources. The Heze area of Shandong Province has attracted canning companies from Fujian and other places to build factories because of its rich asparagus planting resources; Xuzhou, Jiangsu, Suzhou, Anhui and other places have attracted many Zhejiang canned fruit processing companies to set up shop because of their rich yellow peach resources; Yichang, Hubei The rich raw material resources of the Yangtze River citrus belt have also introduced many Zhejiang canning companies.

The advantages of raw material resources directly trigger the expansion of the scale of the local canning industry, which in turn drives the further promotion of raw material planting. After several cycles, China's canning industry has formed industrial clusters dominated by regions and raw material types: Tomato paste in Xinjiang Industrial clusters; canned orange industry clusters in Zhejiang, Hubei, and Hunan; canned mushroom and canned aquatic product industry clusters in Zhangzhou, Fujian; canned fruit industry clusters in Xuzhou, Suzhou, and Linyi; canned meat industry clusters in Sichuan and Chongqing; canned meat industry clusters in Jieyang, Guangdong The canned bamboo shoots industry cluster; the Mengzong canned bamboo shoots industry cluster in Zhejiang and Fujian; the canned dace fish with black bean sauce industry cluster in Guangdong; the sweet corn industry cluster in Changli, Qinhuangdao;...

In 2015, China exported 2.91 million tons of canned goods, with an export value of US$4.98 billion. Among them, there are 7 tax codes with an export scale of more than 100,000 tons. The export volume of each tax code is as follows: canned tomato paste (>5kg) (export volume 564,000 tons; export value 499 million US dollars), canned tomato paste (≤5kg) ) (423,000 tons; US$415 million), canned citrus (318,000 tons; US$326 million), canned white mushrooms (185,000 tons; US$254 million), canned peaches (155,000 tons; US$189 million), Other canned vegetables (this is a separate tariff number listed by the customs, 129,000 tons; US$257 million), canned bamboo shoots (125,000 tons; US$205 million).

Compared with the international market, the expansion of China's canned domestic market is relatively slow. However, some regions and some varieties of canned products have developed rapidly mainly relying on the domestic market. The canned dace processing industry with black bean paste in Guangdong, the canned fruit processing industry in Pingyi County, Linyi County, Shandong Province, and the canned sweet corn processing industry in Changli, Qinhuangdao, etc. all developed by relying on sales in the domestic market. In addition, many canned food processing enterprises that relied on export trade began to focus on the domestic market after entering the new century, pursuing both domestic and foreign sales, and have also achieved certain results. Xiamen Gulong, Shanghai Meilin, Guangzhou Eagle Money, Xiamen Yinlu, Hunan Guoxiu, Guangdong Yuehua, Fujian Zishan, Fujian Xing, Fujian Gangchang, Shandong Linyi Kangfa, Shandong Linyi Tiantong, Zhejiang Fengdao, Fujian Quanzhou Xido A number of excellent brands such as Duo, Suzhou Technology and Qinhuangdao Marine Food have already occupied a certain share in the domestic market. Canned rice-treasure porridge, canned luncheon meat, canned braised meat, canned fruits from the north and south, canned dace with black bean sauce, canned meat sauce, canned tomato sauce, canned bamboo shoots, canned sweet corn, etc. have become the main force in China's domestic canned market.

There is a demand for military canned food every year, and many canned companies have obtained production orders through bidding. As disaster relief food, canned foods often become indispensable for food supplies in disaster areas. When the SARS epidemic broke out in Beijing in 2002, the canned products in the stores were sold out. Xiamen Gulong Canned Food Co., Ltd. worked overtime to produce canned meat rice dumplings with southern Fujian flavor and transported them by sea to Beijing to express condolences to medical workers fighting SARS; in 2008, the Wenchuan earthquake in Sichuan After the disaster, the first batch of food dropped by helicopter to the disaster area was canned meat produced by Sichuan Meining Canned Food Co., Ltd. With the deepening of international cooperation, Chinese canned goods have been continuously transported abroad through special channels for many years as supplies purchased by the United Nations or humanitarian relief supplies from China.

Since the National Bureau of Statistics includes protein drinks such as almond milk, coconut milk, and milk peanuts into the statistics of canned products, China's canned production has grown rapidly in recent years in terms of output. It can be believed that part of the substantial growth in domestic canned production released by the National Bureau of Statistics of China belongs to protein drinks and some flavored foods without added preservatives, including soft-packaged cans. The total output of canned food in 2015 was 12.126 million tons. It is calculated according to "total output - export volume + import volume = apparent consumption in the domestic market". Since the import volume is relatively small at first, it can be ignored, so China's domestic market in 2015 The apparent consumption of canned food in the year is 9.212 million tons. Based on the population of mainland China being 1.36 billion, the per capita consumption of canned food in China is 6.77 kilograms.

Contact Us

Your email address will not be published. Required fields are marked*